Boa’s H+i1 system has a wonky name, but its creators promise better pressure distribution, adjustability and control that ultimately lead to better skiing.

Boa Technology has an entire team dedicated to breaking things. Its job is to find the limits of the company’s products, then push them further. Build, break, repeat.

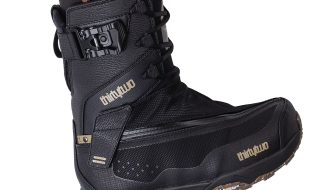

Take the H+i1 system, found in alpine and touring boots from eight manufacturers (Atomic, Dalbello, Fischer, K2 Skis, Head, Nordica, Salomon and Tecnica). Though Boa Fit Systems are used in athletic footwear the world over—even lightweight ski mountaineering boots—alpine skiing was a gap for the company. Cables running along the outside of the boot shell needed to be strong enough to close the stiff plastic and withstand abrasion from a ski edge. Back in 2016, nothing in the company’s lineup held up.

So, Boa’s team of saboteurs assembled. In the basement of the company’s otherwise modern headquarters in Denver, the engineering department is a physics geek’s paradise. CNC machines and computer monitors sit next to boxes that flex a boot thousands of times until the steel cables fray.

In that dungeon of destruction and rebirth, the engineers took the H4, their biggest dial and cable from snowboard boots, and slapped it on a ski boot. Results were … predictable. “We got to measure all the ways it broke, which let us decide what we needed to improve, what aspects needed to change in order to come up with a system robust enough to close the plastic shells of a ski boot,” says Brenna Sullivan, public relations and communications manager at Boa.

That instructive failure set the course for the five-year development of the H+i1 system. Like all Boas, it has a dial, cable and guides. You spin the dial to tighten the cable until you find the right fit. You pop the dial to loosen it so you can remove the boots. If you’ve seen one Boa, you’ve seen them all, right?

Wrong. The H+i1 is decidedly burlier than any Boa you’ve seen. One hundred strands of steel are woven into the wire, offering 250 kilograms of closing force, more than two-and-a-half times what’s needed for skiing, according to the company. The dial, obviously, is strong enough to ratchet that bigger cable, and it has one distinct advantage over other Boas: It’s multidirectional, meaning you can reverse it to ever-so-slightly loosen the cable, a microadjustable nature that enables you to more easily find your fit.

You might ask yourself, “I’ve been skiing with buckles since my mom put an Edgie-Wedgie on me and pushed me down Buttercup. Why change now?” Fair question, but deep down you know ski boots are uncomfortable. You also had to go into the lodge so Mom could get you hot cocoa because the buckled boots hurt your feet.

At Boa’s headquarters a couple of summers ago, I stuck my feet and a set of pressure sensors into a pair of buckle boots and closed them tightly. A computer monitor displayed the pressure exerted on my feet (green equaled less, red more), and as I crouched into skiing form, red lines—and discomfort—shot across the top of my foot. We tried again with a boot featuring the H+i1 system. Besides yellow splotches at my instep and sixth toe, the color remained green, proof that the pressure was more evenly distributed.

Therein lies the crux of Boa’s claim: You get better performance and comfort with the H+i1 than traditional buckles. “Significantly better pressure distribution, more microadjustable, improved power transfer to your ski, and superior stability and control and turns are all things we have proven in our lab,” Sullivan says. When she says proven, she means it.

Boa engineers published a study in the peer-reviewed journal Frontiers in Sports and Active Living delving into the benefits of ski boots equipped with Boas, rather than buckles. Top of the foot pressure decreased by 13%, while skiers applied 6% more peak force while turning and 10% more force at turn initiation. My journalistic mentors always told me to take internal studies with a grain of salt, but it’s hard to argue with more comfort and more power.

As a snowboarder, I’ve watched friends fiddle with tiny parts to repair a Boa in the backcountry. Sullivan says the H+i1 solves that problem. It has a bayonet-and-cartridge system, meaning the dial simply plugs into a port on the boot, and if it pops off, you stick it back on. Having watched one of Boa’s engineers wail on a boot, it’s clear popping the cartridge off in the first place is tough, but the claims of easy install hold up.

For now, the H+i1 is found mostly on crossover-type touring boots—think the Atomic Hawx line—but Sullivan says Boa is always expanding into new models, so your number of options will likely continue to grow. You just have to ask yourself if you’re ready to make the change.

Get the 2026 Gear Guide

After months of testing—including our weeklong Powder Mountain test and tours across North America—our editors narrowed down hundreds of products into the best skis, splits, boots, bindings and outerwear.

Get your copy today👇 | Learn more »

Related posts: