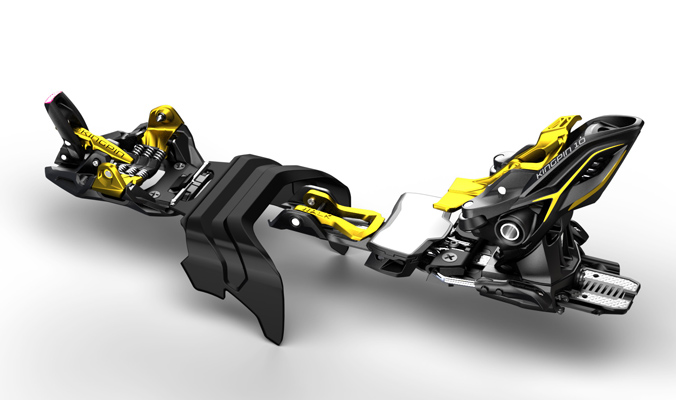

Four years ago, Michi Buechers, an IFMGA-certified guide with a background in biomechanics, began working at Marker International. As binding product coordinator, he managed the team of three engineers who developed Marker’s first-ever tech binding, the Kingpin, which they debuted last week in Nevados de Chillan, Chile.

While tech bindings have traditionally offered safety release at the toe and/or heel, the Kingpin is the first to meet DIN ISO 13992:2007. That means it’s the first tech binding acknowledged by the TUV—the international certification body that validates product safety—to offer a certified DIN safety release. The Kingpin has a traditional tech-style toe and an alpine-like heel that offers lateral and vertical release. It will be available in December.

After three days of testing in corn, on ice and hardpack, I sat down with Michi to talk about developing the Kingpin, the challenges of building a binding from scratch and the future of tech bindings.

![Michi Buechers with the binding he helped develop in front of Volcan Chillan Nuevo, Chile. [Photo] Tyler Cohen](https://backcountrymagazine.com/wp-content/uploads/2014/09/kingpin2.jpg)

Michi Buechers with the binding he helped develop in front of Volcan Chillan Nuevo, Chile. [Photo] Tyler Cohen

Michi Buechers: When I started with Marker, we had the F10 and F12, but we felt we really hadn’t reached the touring market. We saw this pintech market growing, and I knew from my experience that it’s really a difference to tour with. It was obvious that, if we wanted to reach the touring market, it made sense to do it with a pintech binding. But we knew we didn’t want to make a “me too” product….we wanted to create something new.

BCM: Did you see a big demand that you needed to fill?

MB: Yeah, of course. That was part of it. We also heard of problems with existing bindings, and we saw some potentials. Not a lot of products are perfect, and we saw lots of potential in the pintech.

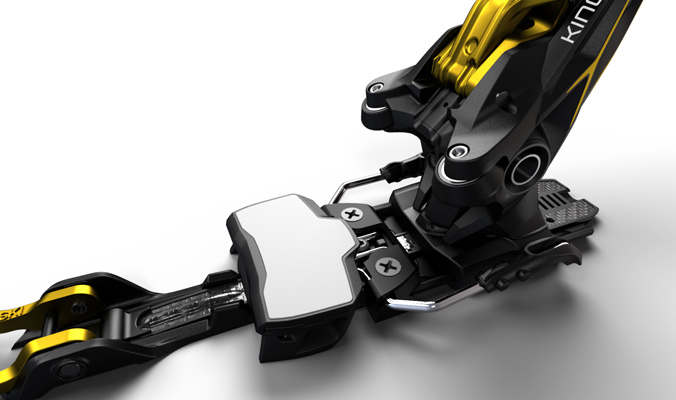

![The Kingpin toe has six springs designed to improve retention. The small, black tabs are boot bumpers, intended to aide ease of entry. [Photo] Tyler Cohen](https://backcountrymagazine.com/wp-content/uploads/2014/09/kingpin4.jpg)

The Kingpin toe has six springs designed to improve retention. The small, black tabs are boot bumpers, intended to aide ease of entry. Mode change is achieved using the gold, underfoot lever. All the gold parts are forged aluminum and built by climbing-gear maker DMM. [Photo] Tyler Cohen

MB: When we started [three years ago], that was a time when a lot of companies opened their eyes. There was the certain point when it was obvious that this part of the skiing market was growing. All of the sudden, that market got very interesting for several companies.

BCM: Do you see most of the growth among people wanting tech bindings in Europe or the U.S.?

MB: Both. In Europe it depends a little bit on the country. There are some countries where there are already 80 percent using pintech bindings, but there are some more conservative countries using mostly frame bindings. I think there was a turning point maybe two or three years ago where you saw more and more people using that pintech binding; people getting more aware of that system.

![The Kingpin locked out and in tour mode. The heel offers two risers (7 and 13 degrees) in addition to a flat tour mode. [Photo] Tyler Cohen](https://backcountrymagazine.com/wp-content/uploads/2014/09/kingpin5.jpg)

The Kingpin locked out and in tour mode. The heel offers two risers (7 and 13 degrees) in addition to a flat tour mode. [Photo] Tyler Cohen

MB: Of course there were many small details that we had to improve during the process, but in the end I think the hardest part was to find the right concept, the big picture. We had targets we wanted to reach in the end: we wanted DIN certification; we wanted a stronger heel; we wanted the handling [to be] as least as good as existing bindings; we wanted it lightweight. To pack all these points into a concept without creating a new boot standard was a big challenge and took us a long time.

BCM: Do you think there’s been a race of sorts to become the first binding that is DIN ISO certified?

MB: Yeah. It looks like there are some other brands in the starting position. I think [getting our certification first] shows the knowledge of binding development in this company and what a strong team we have.

BCM: What are some of the challenges you see with getting this binding out there?MB: It looks heavier than it actually is, and I think we need to get people’s hands on it and show them that it’s not a big difference. For sure, it’s going to be a challenge to explain to people. It only weighs one chocolate bar more than some other pintech bindings.

BCM: Until now, tech bindings have been made by niche-specific, backcountry-focused brands. What does it mean for the sport that Marker, the big binding company, is making a tech binding?

MB: It shows that sport has really grown in the last years. But the other question could be what does it mean for Marker? At the beginning we didn’t know if we could compete with all the specialized brands. But when I look at our whole team, I think it’s all been pretty authentic. I think that the crew that is behind this is very much committed to this sport.

![The Kingpin will be available in DIN 5-10 and DIN 6-13 versions. It weighs 3 lbs. 3 oz. with brakes. [Photo] Tyler Cohen](https://backcountrymagazine.com/wp-content/uploads/2014/09/kingpin3.jpg)

The Kingpin will be available in DIN 5-10 ($599) and DIN 6-13 ($649) versions. It weighs 3 lbs. 3 oz. with brakes. [Photo] Tyler Cohen

MB: I think the sport is getting more and more nuanced. It’s all skiing, but touring is one thing, and even within touring there is racing, doing big traverses, free touring. So it’s getting more and more nuanced, and I think, for the whole binding and ski market, there will be products for every niche. Some products will have the potential to cover more of these niches and some will be more specialized.

For more on the Kingpin and a detailed review, stay tuned to backcountrymagazine.com. Visit marker.net/kingpin for more technical details.

[Update – September 10, 2014: According to Dynafit, the world’s first TUV-certified frameless tech binding was the original TLT4, which received certification for ISO13992 in 1994. Since then, the testing procedures have evolved to include more combined loading tests, and the Marker Kingpin and Dynafit Beast 16 are now TUV certified under the updated standard, ISO 13992:2007.]

![Various Kingpin concept heels and the real thing. [Photo] Tyler Cohen](https://backcountrymagazine.com/wp-content/uploads/2014/09/kingpin8.jpg)

How much does it really weigh? There are pretty heavy chocolates bars out there!

According to Marker, 3lbs. 3oz. with brakes. —Tyler Cohen, Editor

Actually, to be truly honest, Marker’s binding weight includes everything, right down to the screws, this from a conversation with Marker-Volkl USA. Some other manufacturers give WEIGHTs of just the major binding components and omit the little bits. It all adds up…

Any idea about availability this winter?

Marker says they’ll be available in limited quantities beginning December 15. —Tyler Cohen, Editor

So what about the functions, like swapping from walk to tour and back, and heelifts. No real info on those, which in my opinion have just as big an impact on the efficiency of the system as weight. Also last years new pin Binding delivered by frittschi had very serious problems with the REMOVABLE steel pins threading into an aluminum housing. What did marker do to insure their design is sufficiently robust?

Rob: As the binding isn’t yet available, we haven’t tested it extensively, however I spent three days touring on it and found it very user friendly. Raising and lowering the heel risers was a challenge at first, but I figured out a new method where it’s easily done with the side of the pole tip, rather than the basket. Mode changes are extremely simple and can be done without removing skis (good luck putting skins on without removing skis though). To tour, you keep the toe engaged, release the heel, like on an alpine binding, then slide the mode-change back to tour. Reverse the process to lock into ski mode.

As for the pins, those of the Fritschi were designed to be adjustable (they’ve since changed the design for ’14/15 models). This is not the case with the pins on the Kingpin. And we were told that the gold parts are forged aluminum and made by climbing-gear brand DMM. —Tyler Cohen, Editor

Okay, so they are about 10 ounces lighter than Marker’s F10 bindings and obviously will be better for walking and climbing. But what about actually skiing? Which is better? Which is safer?

Just curious if the crampon slot will accommodate Dynafit crampons? Looks like the same design, but unsure about the dimensions. Anyone tested this out?

I am currently a tele skier eyeing transitioning to AT/Rando (we do get older) 🙂 Here is an article from Evo that has more details about the actual binding functions:

http://culture.evo.com/2014/09/marker-kingpin/

The big things to note is there are no heel pins, but wide jaws with rollers, and the heel piece slides back instead of rotating to change modes.

I have a pair of the Marker Kingpin 13 and skied them in Colorado for an entire season from 14ers to hardpack. They skied great downhill and released properly and had the feel of an alpine binding. On the uphill, I have had multiple releases while the toe was supposedly locked out. I ended up losing my ski because of this recently. I would not recommend them because of this and have not heard back from Marker regarding this problem.

Marker has been much more responsive and it looks like they had some issues with the pins on the first round they manufactured. They are very helpful after I spoke with them and are resolving this problem. I am very excited because I really enjoyed the binding and they have been great at the resorts and in the backcountry where I routinely take the up 3000 vertical or more. Very satisfied.