In the November 2014 issue, Editor Tyler Cohen explores the recent boom in tech bindings that have an increased focus on safety—and DIN certification. While researching this story, he posed several questions to four leaders in the binding industry, Fritz Barthel, the inventor of the Low Tech system, Edwin Lehner, lead binding designer with Dynafit, Jeff Campbell, a PhD candidate studying binding mechanics, and Dr. Irving Scher, chairman of the American Society for Testing and Materials’ International Snow Skiing Committee. Here’s what they had to say.

Backcountry: What’s the difference between a release value and certified DIN setting?

Jeff Campbell: The release value of an alpine ski binding is directly related to the amount of torque required to release the boot from the binding. The binding’s indicator setting (commonly but incorrectly called a DIN setting) adjusts release value. Indicator settings for traditional tech/pin bindings are different from those found in typical alpine/AT frame bindings, and a traditional tech/pin binding set to an indicator setting will not release at the same torque value as an alpine or AT frame binding with the same indicator setting.

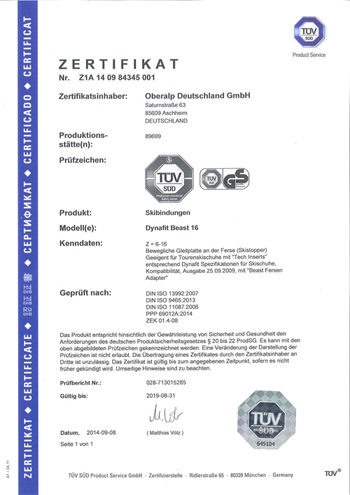

BCM: What does TÜV certification mean for the consumer?Edwin Lehner: TÜV certification means [that the consumer] can be sure the binding fulfills all requirements written in DIN ISO 13992. There are a lot of aspects like binding freezing, pollution with mud and salt, release during ski flex and a lot of other conditions where the binding has to release. A not-certified binding can fulfill all this requirements, but the TÜV certification attests it from an independent office, and TÜV proofs the production of the binding every year.

Dr. Irving Scher: For the consumer, TÜV certification means a binding meets the minimum performance requirements specified by safety standards from the International Standards Organization (ISO). For traditional alpine ski equipment, it provides the consumer with a level of confidence that an alpine bindings will perform as desired with any alpine ski boot, providing a minimum level of protection of lower leg injury and inadvertent releases.

BCM: Is TÜV certification the end-all/be-all of binding safety?

Edwin Lehner: More or less yes, but a binding can be in between the tolerances of requirements. The DIN ISO [standard] also will be approved and, if necessary, changed every five years.

Dr. Irving Scher: It is a positive step forward, but there is much work to be done. For example, TÜV certification of an alpine binding to ISO standards means the boot/binding system will reduce the likelihood of lower leg injuries, particularly boot-top fractures and spiral fractures of the tibia and fibula. On the other hand, the standards (and therefore the certifications) do not address preventing knee injuries that are prevalent in skiing.

BCM: Tech bindings have been around for 30 years. Why are we suddenly seeing so many come to market?Jeff Campbell: A big catalyst to the tech binding boom was the expiration of a key patent, held by Dynafit, in 2005. Competition breeds innovation…that innovation can take time.

Fritz Barthel: When Salewa took over Dynafit in 2003 they were the first to really take [the tech binding] seriously and see some potential in it. There are the “big” players now that want to participate in this trend. Who does not want to be part of the craze? But, of course, the basic motivation of using the “pin” system is the fact that it has easy-to-feel advantages: the weight, the smaller mass moment of inertia, and probably as long as there is not [anything] better coming up, conventional frame solutions are hard to market.

BCM: Why the sudden focus on safety, with four new bindings touting new release mechanisms?Fritz Barthel: Raichle [which owned Dynafit in the ’90s] already had a focus on that issue and had the binding certified by the TÜV in the mid ’90s. It turned out that, for the “crazy specialist,” it did not matter whether there was a TÜV sign or not on the binding. In fact, there was the TÜV stamp on the Dynafit binding for many years. People saw other bindings with TÜV certification emerge, but in practical use they turned out to be not that reliable or functional as the certification seemed to promise and they disappeared again. I feel that the sudden focus now is propelled by the bigger numbers of bindings plus the fact that the binding has left the original “core group.” In this wider group there is more emphasis and demand for certified products.

Jeff Campbell: Tech/pin bindings were originally designed for relatively mellow alpine touring in soft AT boots, not for the aggressive freeriding demanded by consumers today. The original Dynafit binding was mechanically very simple, though the complexity of the binding-boot interaction often underestimated. Stiff, modern AT boots and aggressive skiers can easily overwhelm simple bindings that lack features such as forward pressure. As a result, skiers using tech/pin bindings can feel that their bindings are prone to pre-release and react by locking out the toe while skiing. This is a safety concern and new designs are attempting to address this issue, as well as other potential safety issues.

BCM: What does all this engineering focus aimed at safety and number of products available mean for the backcountry skier?

Dr. Irving Scher: Certification is not a measure of how well a given binding will perform during skiing. Certification means that with a very particular AT boot sole (from an ISO standard), the binding will perform in a manner that is desired to reduce the likelihood of lower leg injury. The problem is that the boots on the market do not meet, in general, the current international standards, and the pin inserts used in these boots are significantly different between manufacturers. With this in mind, at this time, any given set of boots in any given tech/pin binding may provide boot retention and release performance that is different from what skiers have gotten used to with standard alpine bindings.

Fritz Barthel: Competition is good. Companies are pushed to innovate; there is a big choice and a pressure on prices.

Most real backcountry skiers do not care about all of this. The touring bindings have been performing just fine for them for decades. Backcountry skiers want the binding to be lightweight. These new bindings are not lightweight. Freeride skiers should stick to alpine bindings. All of these bindings are chasing an imaginary market segment that does not exist, or else they are trying to create a new market segment that really does not make any sense from a user perspective. The fact that the boot inserts are not being manufactured to the same standards by different manufacturers, makes all of this new push towards TUV certification of limited use. Also, any highly experienced ski tech will tell you that most of the binding testing done by ski shops who mount these bindings is also highly variable and of limited use.

Dear so what,

don’t know why you don’t like the bindings (in my case a limited edition of the Dynafit Beast 16).

I use the Beast 16 with my Huscaran and a pair of Dynafit Vulcans for touring days too, not just for lift assisted freeride days…. Further on i have a pair of Dynafit SevenS with a Radical ST. If i switch the skis on the fly i see a outstanding difference in how the bindings hold my shoe. Further on it depends how well a backcountry skier skis … i do see a lot of people who can’t ski so it makes no difference between product a or b, they screw them up themselfs ….

That these bindings are still a bit of ovekill is a different thing, but i like the downhill and uphill performance of the beast.

Best Regards

The future of telemarking is the garbage dump! Get over it an get some at gear and stop holding everyone up with ur stupid always breaking tele gear. While ur at it take shower and lay off the granola. :-

What, ignoring the safest pin binding in the world. Fritchi Vipec ! Light, with toe elasticity.

Imagine not having to lock your Dynafits.

Was there not enough money exchanged hands at bcmag to actually talk about this amazing binding.

The article is about tech bindings with TUV certification. That is why they also did’t mention TR2 binding by Skitrab which works like the Kingpin. I skied for a while with Fritschi Vipec on my fat K2 skis and i found it very safe and faithful on every kind of snow and I tried TR2 bindings during a test this summer. All of these bindings are very good at building a bridge over the world of freeride (power transmission, precision and safety) and the world of touring (lightness and efficiency in climbing).They had to compromise, but they all are great attempts toward the goal of a light an safe binding superlight uphill and superfun downhill!